Finding Right Cannabis Product: Complete Guide 2025

Finding the right cannabis product requires understanding your consumption preferences, desired effects, and tolerance levels. With over 38 states having legalized cannabis in some form as of 2025, American consumers have access to an unprecedented variety of products including flower, edibles, concentrates, and topicals. This comprehensive guide will help you navigate the complex cannabis landscape to identify products that align with your specific needs and wellness goals.

How to Choose the Right Cannabis Product for Your Needs

Selecting the appropriate cannabis product begins with understanding your personal goals and circumstances. Whether you’re seeking relief from chronic pain, anxiety management, or recreational enjoyment, different products offer varying onset times, duration, and effects. Medical cannabis patients often require different considerations than recreational users, particularly regarding dosing consistency and specific cannabinoid profiles.

Your lifestyle also plays a crucial role in finding the right cannabis product. Professionals who need discretion might prefer edibles or vape cartridges over traditional flower, while those seeking immediate relief may benefit from inhalation methods. Consider factors like your living situation, work schedule, and social environment when making your selection. Additionally, budget considerations are important, as prices can vary significantly between product categories and brands across different states.

Understanding Different Methods of Consumption

The method of consumption directly impacts how you experience cannabis products and plays a vital role in finding your ideal match. Each consumption method offers distinct advantages and considerations that can make or break your cannabis experience.

Inhalation Methods: Smoking and Vaping

Inhalation remains the most popular method for cannabis consumption due to its rapid onset of 2-5 minutes and precise dosing control. Smoking flower provides the full spectrum of cannabinoids and terpenes, while vaping offers a cleaner experience with temperature control options. Vape cartridges have gained significant popularity, with the US vape market expected to reach $7.2 billion by 2025. These products offer convenience and discretion, making them ideal for users seeking portability and ease of use.

Sublingual Absorption and Tinctures

Sublingual cannabis products like tinctures and oils offer a middle ground between inhalation and edibles, with effects typically beginning within 15-45 minutes. This method bypasses the digestive system, providing more predictable dosing than edibles while lasting longer than inhalation methods. Tinctures allow for precise micro-dosing, making them excellent for beginners or those seeking specific therapeutic effects without psychoactive intensity.

Edibles and Oral Consumption

Cannabis edibles represent one of the fastest-growing segments in the US market, with sales increasing by 23% in 2024. These cannabis products offer long-lasting effects of 4-8 hours but require patience due to onset times of 30 minutes to 2 hours. Edibles provide consistent dosing when properly manufactured and are ideal for users seeking sustained relief or those who cannot inhale cannabis. However, they require careful dosing to avoid overconsumption, as effects cannot be easily reversed once consumed.

Product Potency and Cannabinoid Profiles

Understanding potency is crucial when finding the right cannabis product for your tolerance and experience level. THC potency in flower has increased significantly over the past decade, with average THC levels now ranging from 15-25% in most dispensaries. Beginners should start with products containing 2.5-5mg of THC, while experienced users may prefer products with 10-20mg or higher. CBD-dominant products offer therapeutic benefits without psychoactive effects, making them suitable for daytime use or those sensitive to THC.

The ratio of cannabinoids significantly impacts your experience with cannabis products. Balanced THC:CBD ratios like 1:1 or 2:1 provide therapeutic benefits with reduced psychoactive intensity, while high-THC products offer stronger recreational effects. Emerging cannabinoids like CBG, CBN, and Delta-8 THC are creating new product categories, with CBG showing promise for focus and energy, while CBN is marketed for sleep support. Understanding these profiles helps you select products that align with your specific needs and desired outcomes.

The Role of Terpene Profiles in Product Selection

Terpenes play a crucial role in finding the right cannabis product by influencing both aroma and effects through the entourage effect. These aromatic compounds work synergistically with cannabinoids to create unique experiences. Myrcene, the most common terpene, promotes relaxation and sedation, while limonene offers mood elevation and stress relief. Pinene can enhance alertness and memory, making it ideal for daytime consumption.

Modern cannabis products increasingly highlight terpene profiles on packaging, allowing consumers to make informed decisions based on desired effects. Linalool, also found in lavender, provides calming effects perfect for anxiety relief. Caryophyllene offers anti-inflammatory properties and can help with pain management. Understanding these profiles enables you to select strains and products that complement your wellness goals and lifestyle preferences, moving beyond simple indica versus sativa classifications.

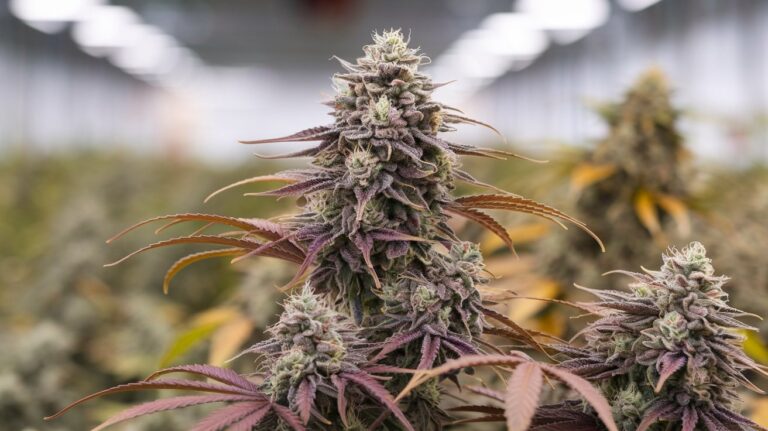

Popular Strains and Products in 2025

The cannabis landscape in 2025 features innovative strains and products that cater to diverse consumer preferences. High-rated strains on platforms like Leafly continue to guide consumer choices, with genetics becoming increasingly sophisticated through selective breeding programs.

Trending Strain Varieties

Several standout strains have gained recognition for their unique profiles and effects. Tippy Toes strain has earned praise for its balanced effects and pleasant terpene profile, while Honest Abe strain offers users a reliable, honest high perfect for social settings. The Metaverse strain appeals to tech-savvy consumers with its futuristic branding and cerebral effects, and Zoy strain provides a cheerful, uplifting experience ideal for creative activities.

Specialty and Craft Cannabis Products

Craft cannabis continues to flourish with unique offerings like the Rodman strain, named after the basketball legend and known for its bold, unconventional effects. Many consumers utilize tools like the Leafly strain match quiz to discover products that align with their preferences and needs. These matching systems consider factors like desired effects, consumption method preferences, and experience level to recommend suitable cannabis products from extensive databases.

Using Technology to Find Your Perfect Match

Digital platforms have revolutionized how consumers discover and select cannabis products. Apps and websites now offer sophisticated recommendation engines that consider your preferences, past purchases, and desired effects. The Leafly highest rated strains feature helps users identify top-performing products based on community reviews and expert ratings, providing valuable insights into product quality and effects.

These technological tools analyze vast databases of strain information, user reviews, and scientific data to make personalized recommendations. Many platforms now integrate AI-driven suggestions that learn from your feedback, continuously improving their recommendations. This data-driven approach to finding the right cannabis product eliminates much of the guesswork traditionally associated with cannabis selection, especially beneficial for newcomers to the legal cannabis market.

Legal Considerations and State Regulations

Navigating legal cannabis products requires understanding your state’s specific regulations, as laws vary significantly across the United States. As of 2025, recreational cannabis is legal in 23 states plus Washington DC, while medical cannabis is permitted in 38 states. Purchase limits, possession amounts, and consumption locations differ by jurisdiction, affecting which products you can legally obtain and use.

Compliance with state tracking systems ensures you’re purchasing legitimate cannabis products from licensed dispensaries. Many states require extensive testing for pesticides, heavy metals, and potency, providing consumers with detailed certificates of analysis. Interstate transport remains federally prohibited, so products must be purchased and consumed within the state of purchase. Understanding these regulations helps you make informed decisions while staying within legal boundaries and accessing the safest, highest-quality products available.

Budget-Friendly Options and Value Considerations

Finding quality cannabis products within your budget requires understanding pricing structures and identifying the best value options. Premium products often command higher prices due to superior cultivation methods, testing protocols, and brand reputation. However, many mid-tier products offer excellent quality at more accessible price points, particularly house brands from established dispensaries.

Bulk purchasing, loyalty programs, and daily specials can significantly reduce costs for regular consumers. Many states offer reduced pricing for medical patients through tax exemptions or special discount programs. When evaluating value, consider factors beyond initial cost, including potency per dollar, product longevity, and consistency of effects. Smart consumers often find that investing in higher-quality cannabis products provides better overall value through superior effects and more predictable experiences, even at slightly higher upfront costs.

Related video about finding right cannabis product

This video complements the article information with a practical visual demonstration.

Questions & Answers

How do I know which cannabis product is right for me as a beginner?

Start with low-dose products containing 2.5-5mg THC or CBD-dominant options. Consult with dispensary staff about your goals, choose products with clear labeling and dosing instructions, and begin with inhalation methods for better control over effects. Consider using strain matching tools like the Leafly quiz to identify suitable options based on your preferences and experience level.

What’s the difference between indica, sativa, and hybrid cannabis products?

While traditional classifications suggest indica for relaxation and sativa for energy, modern cannabis science focuses more on cannabinoid and terpene profiles. Hybrids combine characteristics from both types. Instead of relying solely on indica/sativa labels, examine the specific cannabinoid ratios and terpene profiles to better predict effects and find products that match your needs.

How long do different cannabis products take to work and how long do effects last?

Inhalation methods work within 2-5 minutes and last 1-3 hours, sublingual products take 15-45 minutes with 2-4 hour duration, while edibles require 30 minutes to 2 hours onset but provide 4-8 hours of effects. Understanding these timelines helps you choose products that fit your schedule and avoid overconsumption by waiting for full effects before taking more.

Are expensive cannabis products always better quality?

Price doesn’t always indicate quality, though premium products often feature superior cultivation, testing, and processing methods. Mid-tier products from reputable brands frequently offer excellent value. Focus on third-party lab testing results, cannabinoid profiles, and user reviews rather than price alone. Many house brands and established mid-range products provide consistent quality at accessible prices.

How do terpenes affect my cannabis experience?

Terpenes influence both aroma and effects through the entourage effect with cannabinoids. Myrcene promotes relaxation, limonene elevates mood, pinene enhances alertness, linalool provides calming effects, and caryophyllene offers anti-inflammatory benefits. Understanding terpene profiles helps you select products that align with your desired effects, whether for relaxation, focus, creativity, or specific therapeutic needs.

Can I travel with cannabis products between legal states?

No, interstate transport of cannabis remains federally prohibited even between legal states. You must purchase and consume products within the state where they’re legally obtained. Each state has different laws regarding possession limits, consumption locations, and product types. Always research local regulations before traveling and never attempt to cross state lines with cannabis products, as this remains a federal offense.

| Key Aspect | Important Details | Benefit |

|---|---|---|

| Consumption Method | Inhalation: 2-5 min onset, Edibles: 30min-2hr onset | Choose based on desired timing and duration |

| Potency Selection | Beginners: 2.5-5mg THC, Experienced: 10-20mg+ | Prevents overconsumption and ensures optimal experience |

| Terpene Profiles | Myrcene (relaxing), Limonene (uplifting), Pinene (focus) | Targeted effects beyond basic THC/CBD ratios |

| Legal Compliance | 38 states medical legal, 23 states recreational legal | Safe access to tested, regulated products |

| Technology Tools | Leafly strain quiz, dispensary apps, user reviews | Data-driven product selection and recommendations |